With the continuous evolution of textile printing technology, digital textile printing has emerged as a relatively new player in the field, especially compared to traditional analog methods like rotary and screen printing. Nevertheless, the rapid adoption of digital inkjet printing has secured its place in the global textile printing industry, experiencing significant growth. Today, digital textile printing presents numerous exciting opportunities for the industry, seemingly eliminating all constraints on creativity. In this article, we comprehensively compare digital printing and screen printing based on various parameters.

When opting for digital printing over analog methods, understanding the value and enhancements brought by digital printing—from the manufacturing unit to the end-user—is crucial. Let's explore these differences:

What is Screen Printing?

Screen printing, also known as silk screen printing, has been the preferred method for transferring designs onto fabric for centuries. Historians believe it originated in the Song Dynasty in China, primarily used for decorating silk.

While the process has become faster with the advent of machines, the fundamental concept of screen printing remains the same—it is a method of using a mesh screen to transfer ink onto a substrate. The creation of templates on screens forces ink through the mesh onto the substrate, forming the desired design. This technique is commonly employed in printing on textiles, paper, and other materials, known for its durability and vibrant colors.

What is Digital Printing?

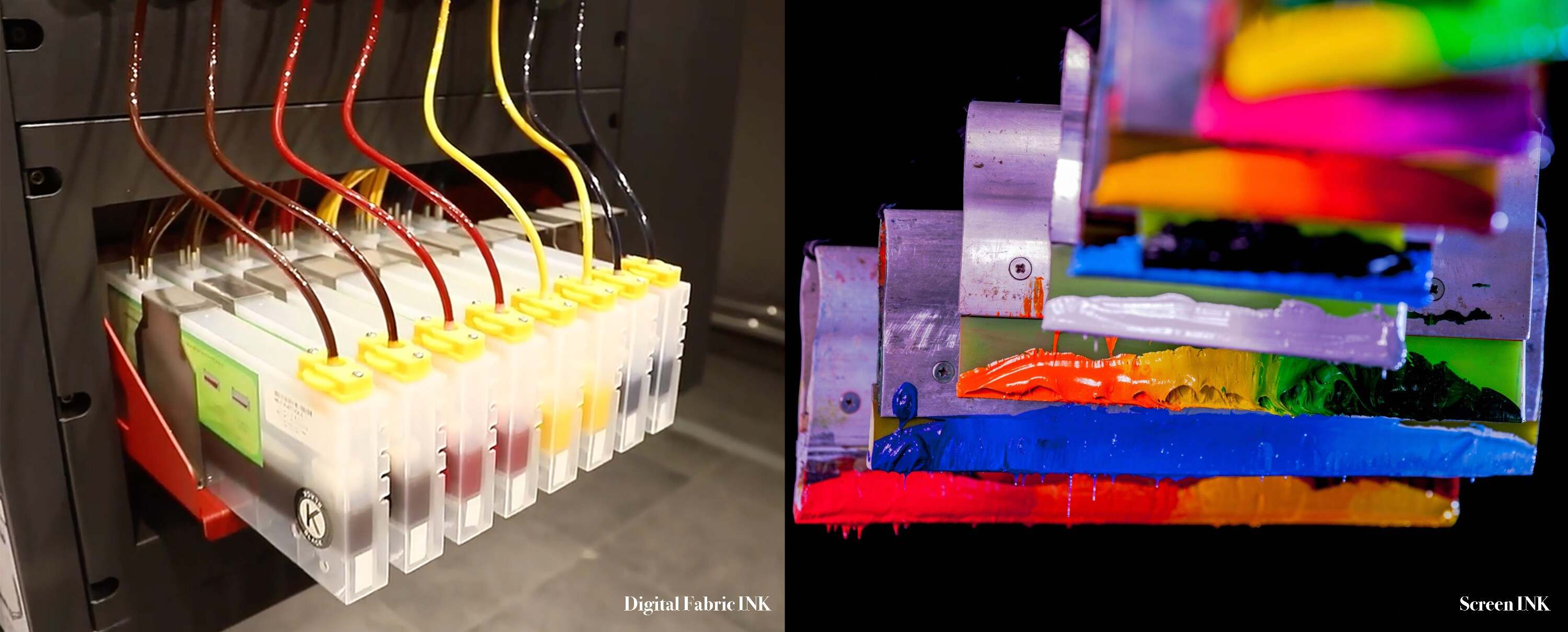

Digital printing is a considerably more automated process that uses computers and digital files to map and place small ink droplets, combining them to create the desired image.

Unlike screen printing, digital printing is a newer technology that has seen significant advancements in the past few decades. As technology has progressed, digital textile printing has become increasingly popular in direct garment printing.

Digital textile printing is a modern method where designs are created digitally and printed directly onto fabric using specialized inkjet printers. It offers flexible customization, precise color control, quick turnaround times, making it an ideal choice for short runs with intricate details and vibrant colors. Compared to traditional methods, this process minimizes waste and has gained popularity in the fashion and other industries.

Comparison of Traditional Screen Printing and Digital Printing:

Comparable Factors | Screen Printing | Digital Printing |

Tools | Involves creating templates by hand or digitally, connecting them to screens, placing them on the desired canvas, and applying ink to the image. | Requires only a computer and a printer with various colored ink cartridges. |

Effort | Time-consuming and labor-intensive due to screen creation and a prolonged process. | Operationally simple, providing results with just a button press, making it relatively faster. |

Quality | Offers higher quality imaging due to deep ink absorption and longer-lasting results. Precision provided by carefully crafted templates also sharpens the edges of printed images. | Direct printing onto fabric prevents ink spread, but colors may fade faster compared to screen printing. However, if a full-color image is desired, where all colors appear in a single image, and individual screens aren't needed. |

Cost | Costs increase with the number of screens required. Creating separate slides for each color is necessary for more complex images. Skilled labor adds to costs. | Computer and printer are one-time investments, making digital printing cheaper per printed image compared to screen printing. |

Advantages and Disadvantages of Screen Printing and Digital Fabric Printing:

Advantages of Screen Printing:

Cost-Effective: Ideal for large-scale production, especially for printing large quantities of the same design, where costs can be spread over bulk production.

Durability: Inks and pigments used in screen printing are known for their durability, ensuring vibrant colors even after multiple washes.

Versatility: Screen printing is suitable for various fibers and materials, including cotton, polyester, silk, and more.

High Color Density: Achieves high color density, producing full and vibrant printing effects.

Disadvantages of Screen Printing:

Limited Cost-Effectiveness: Costs rise with multiple colors, making it less cost-effective for intricate designs.

Plate Creation Time and Costs: Creating screens for each color is time-consuming and incurs higher costs.

Limited Design Flexibility: Changes in design may necessitate the recreation of screen templates, limiting design flexibility, especially for small-scale production.

Not Suitable for Complex Patterns: Complex patterns and gradient colors may be challenging to achieve, as each color requires a separate screen template.

Advantages of Digital Printing:

Design Flexibility: Offers extremely high design flexibility, enabling the realization of complex patterns, gradient colors, and personalized designs.

Suitable for Small Batch Production: Particularly suitable for small-scale production and personalized customization, eliminating the need for screen templates and reducing initial investment.

Quick Production Cycle: Due to the absence of plate creation, digital textile printing usually boasts a faster production cycle, adapting to fast-paced fashion and custom market demands.

High Resolution: Achieves high-resolution patterns, presenting more intricate details in the printed images.

Green Printing: Utilizes sustainable inks and eco-friendly processes, contributing to environmentally conscious printing.

Disadvantages of Digital Printing:

Color Variations: Colors on screens may slightly differ from printed colors.

High Equipment Costs: Initial investment in digital textile printing equipment can be financially burdensome for small-scale producers.

Limited Applicable Materials: Not all fabric types may be suitable for digital textile printing, limiting applications in certain textiles.

Limited Durability: Some digital printing inks may exhibit faster fading with repeated washes, providing relatively lower durability compared to traditional methods.

In the end, the choice of printing method should be based on the specific requirements, budget, and production scale of the project.

However, with the advent of digitization, the fashion industry is undergoing rapid transformations. People are shifting towards online shopping, requiring a plethora of options to decide what to purchase. Diverse designs are a requirement for any fashion brand to attract customers. The speed of trends, styles, colors, or fashion changes has accelerated significantly. Digital textile printing allows brands to effortlessly print new orders and deliver them to customers within a short timeframe. Considering this advantage, fashion brands worldwide are increasingly inclined to collaborate with digital printing businesses rather than traditional printers.

The rise of digital textile printing is often considered the future of textile printing. MT is a professional manufacturer of digital inkjet printers in China, offering a variety of optimized digital textile printing machines. These printers feature compact structures, overall cost-effectiveness, unique designs, a range of color options, high productivity, and high-quality printing.

MT's digital textile printers can print on various media and are compatible with different types of inks. MTuTech provides a series of unique digital textile printing machines, backed by our extensive knowledge, bringing unprecedented advantages to the industry.